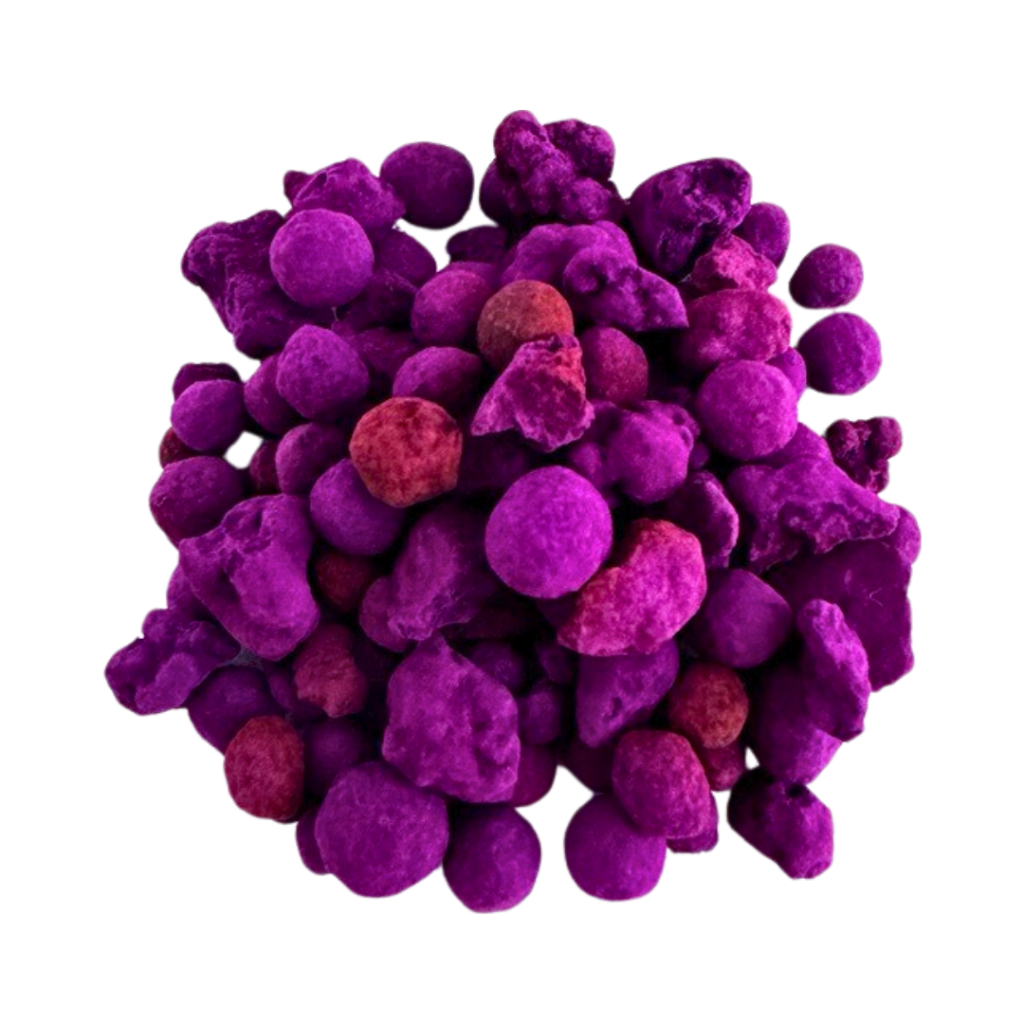

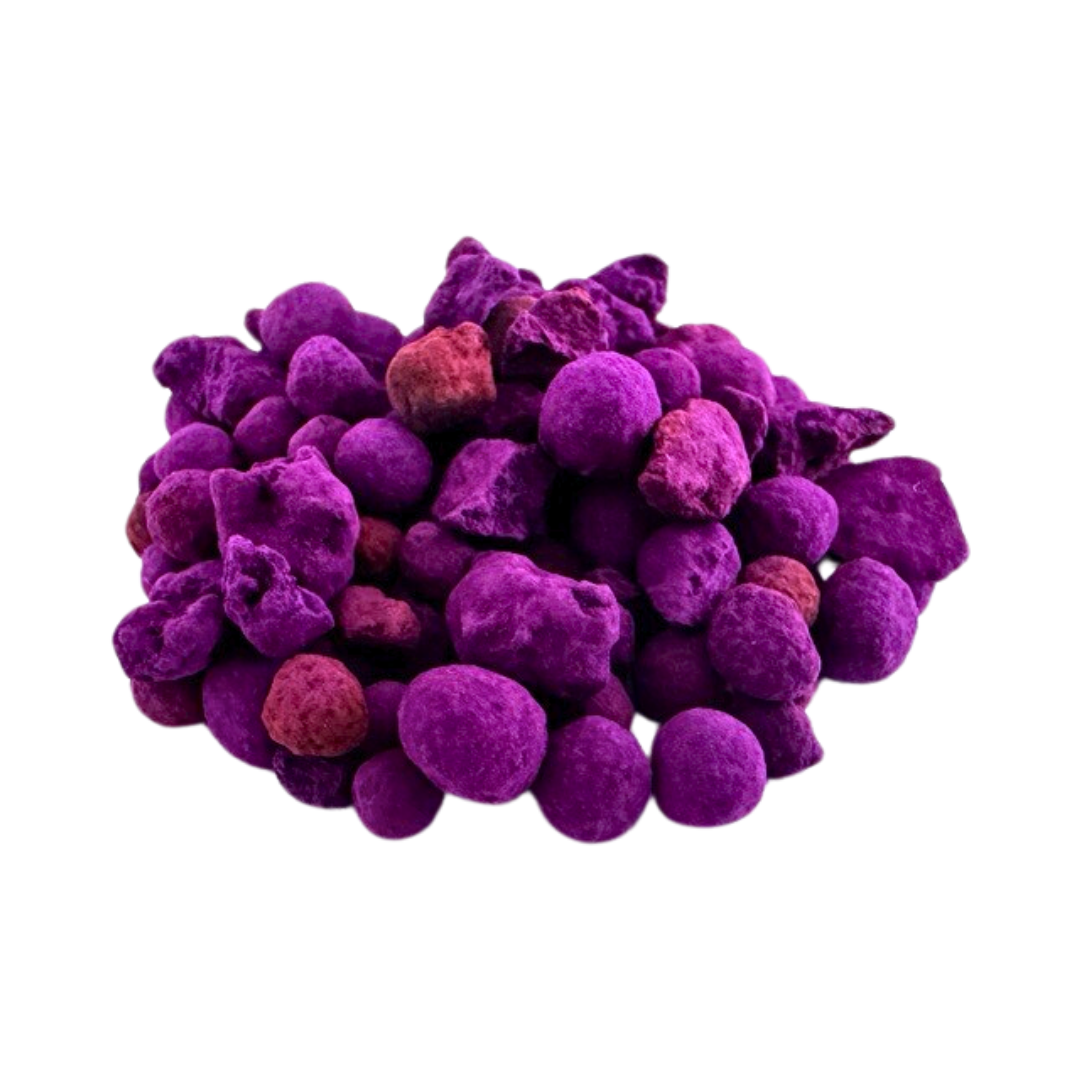

Purafil SP

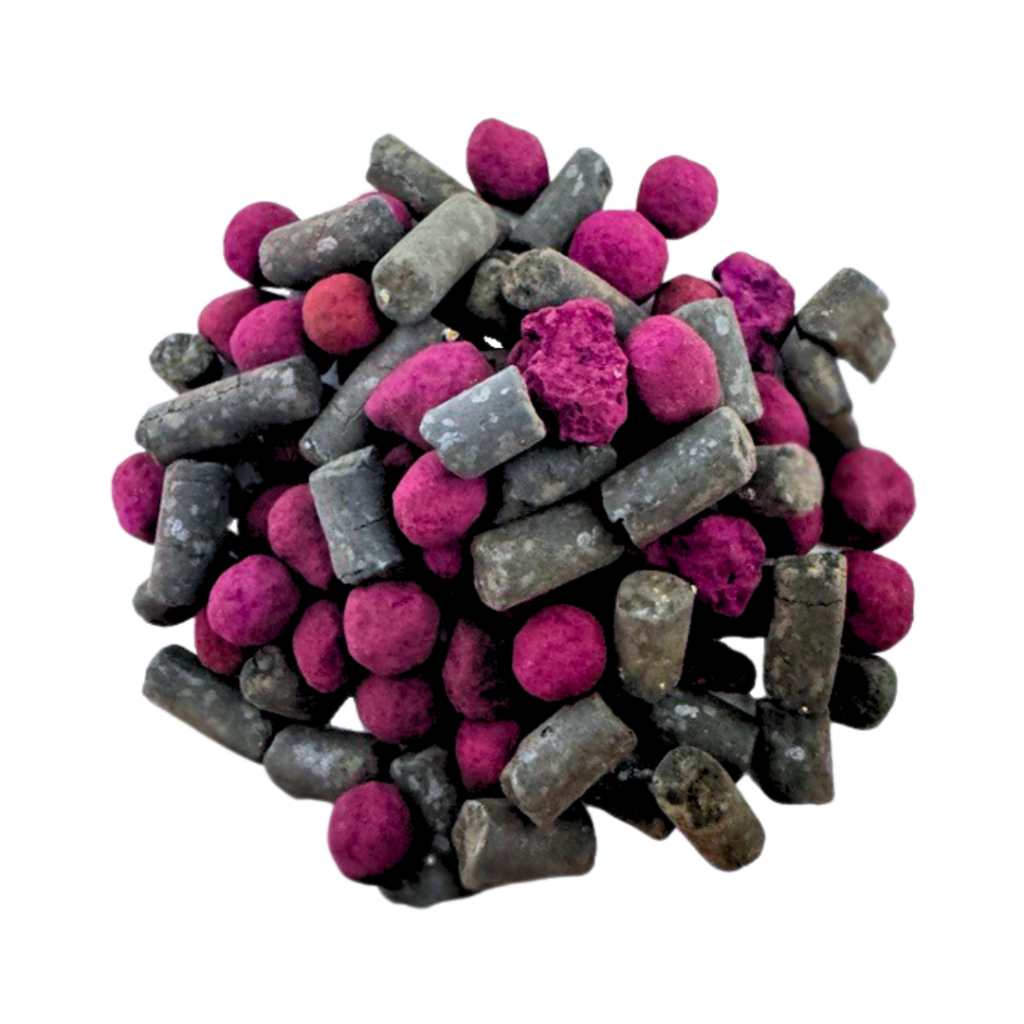

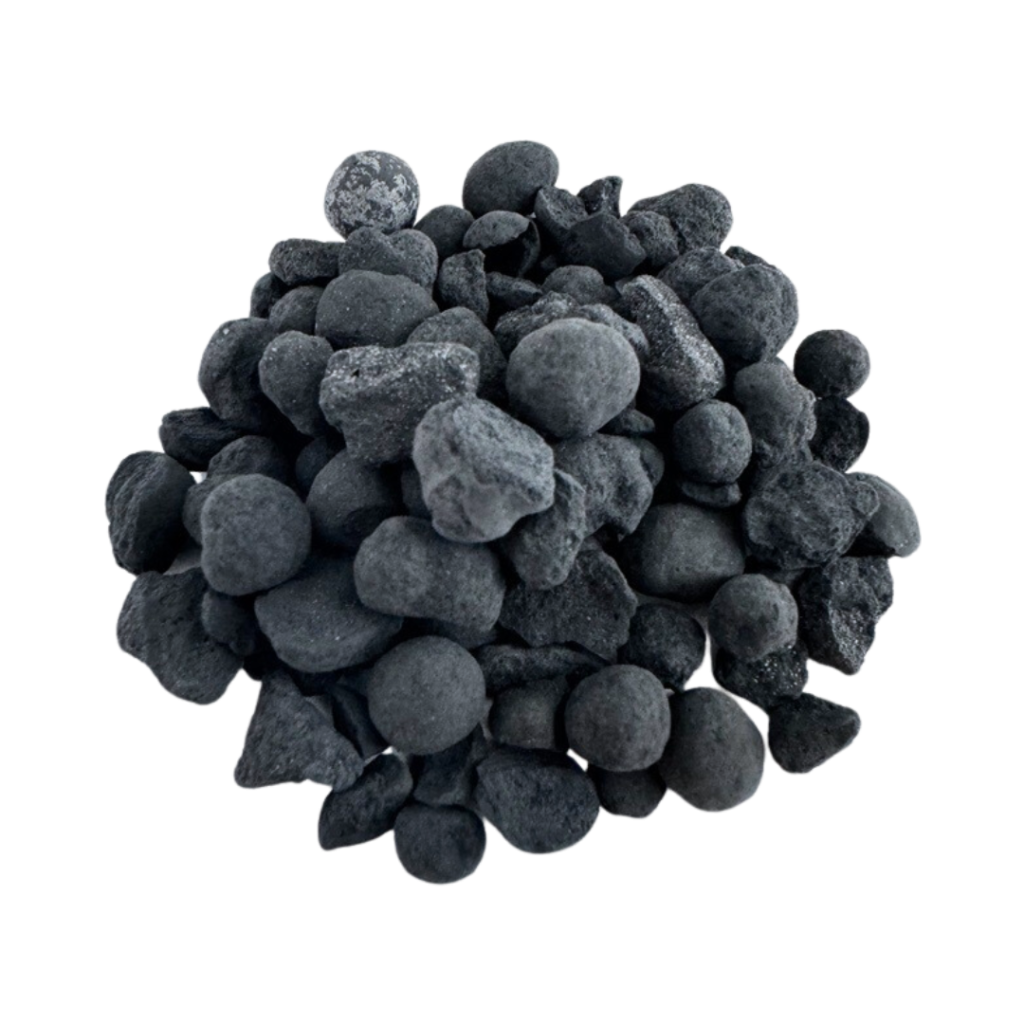

Purafil SP media consists of generally spherical, porous pellets formed from a combination of activated alumina and other binders, suitably impregnated with sodium permanganate (NaMnO4). The sodium permanganate is applied during pellet formation so it’s uniformly distributed throughout the pellet volume and is available for reaction with target gases.

Purafil SP media also offers a higher working capacity for broad-spectrum control for sewerage gases in water/wastewater treatment applications, including hydrogen sulfide, sulfur dioxide, aldehydes, and many organic compounds.

Efficiency

Purafil SP delivers a performance of 99.5% (min) initial removal efficiency in Purafil systems.

Temperature

-4°F to 125°F (-20°C to 51°C).

Humidity

10-95% RH.

Key Features & Benefits

- Effective Gas Removal: Efficiently eliminates hydrogen sulfide, sulfur dioxide, nitric oxide, and formaldehyde.

- High Oxidation Potential: Engineered to provide superior oxidation capacity, ensuring optimal performance in contaminant removal.

- Broad-Spectrum Control: Demonstrates a higher working capacity for broad spectrum oxidation of contaminants where multiple gas challenges are present.

- Non-Toxic and Safe: The chemisorptive process converts harmful gases into harmless solids that remain within the pellet, eliminating the risk of desorption and re-release into the environment.

Your Partners In Clean Air

Call 780-436-6960 today to speak with a BGE Clean Air Advisor.