Puracarb

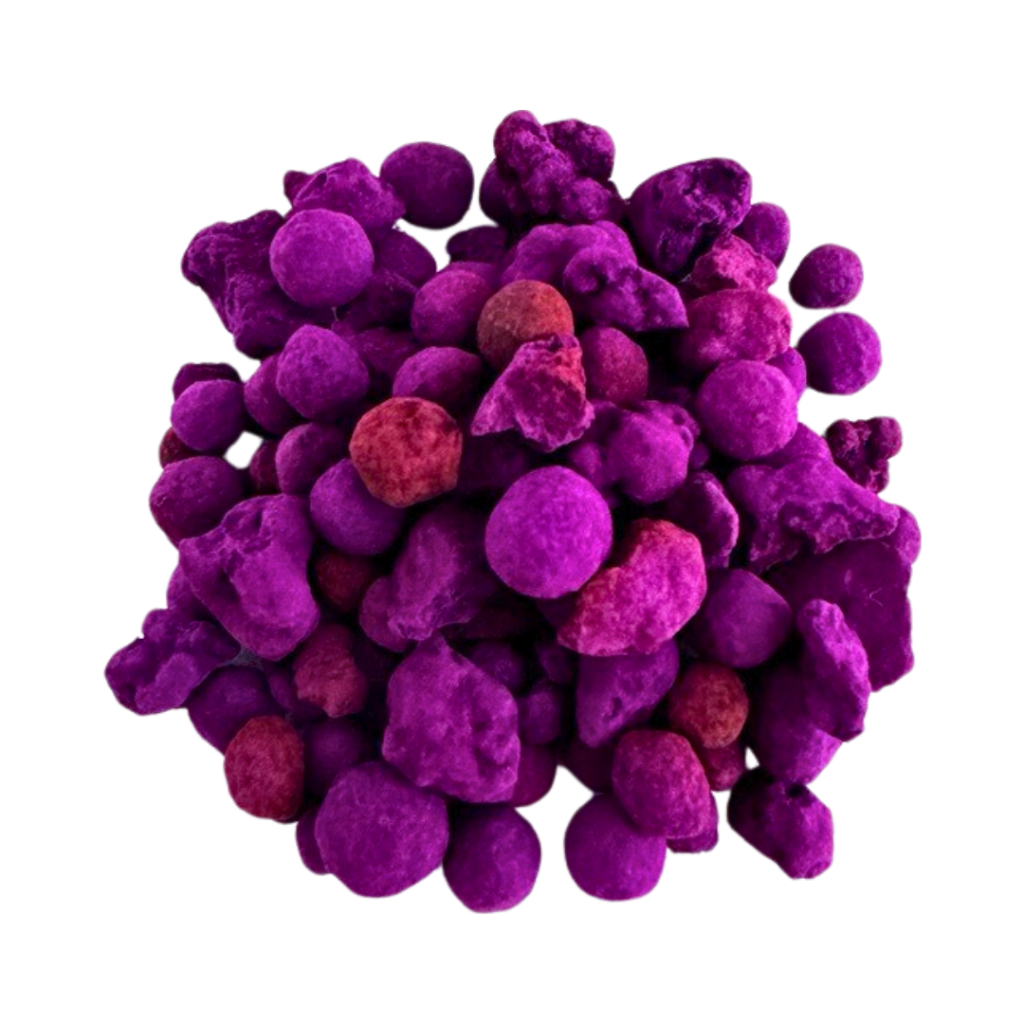

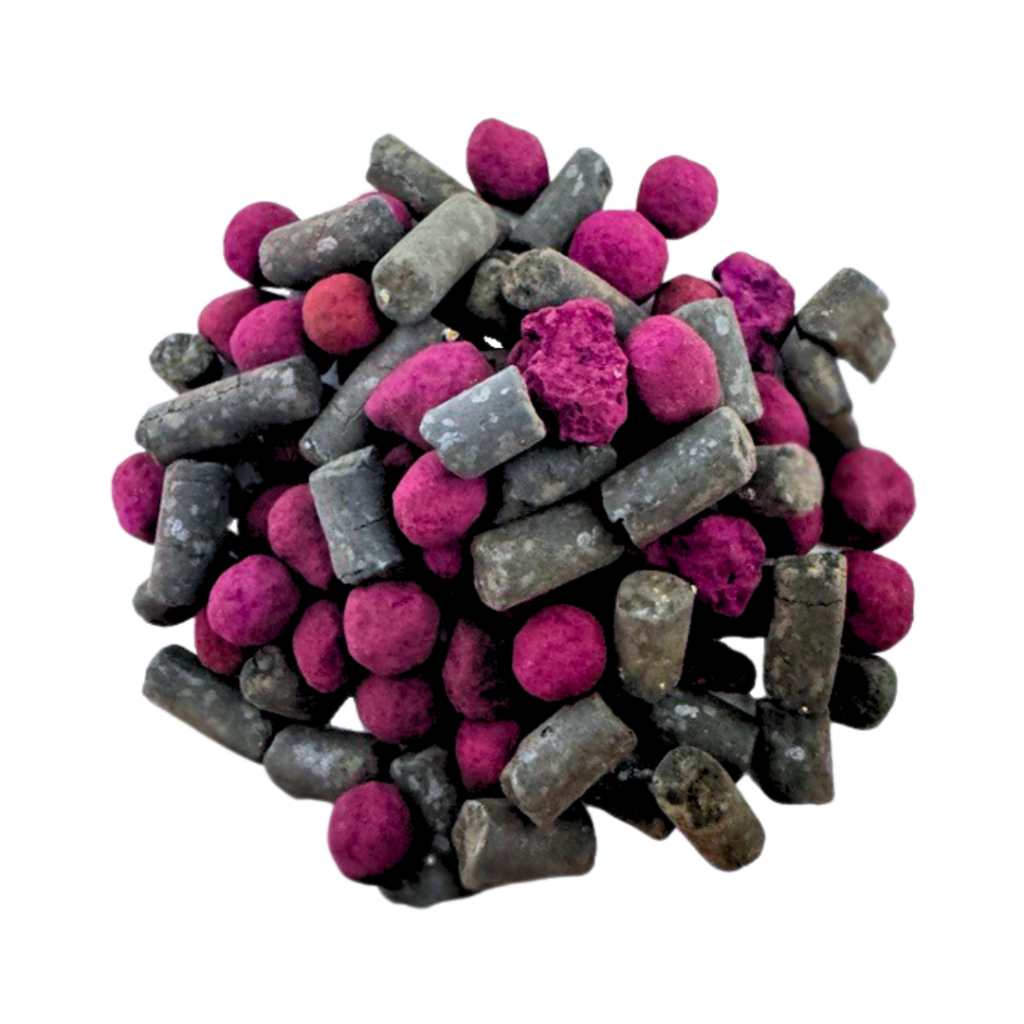

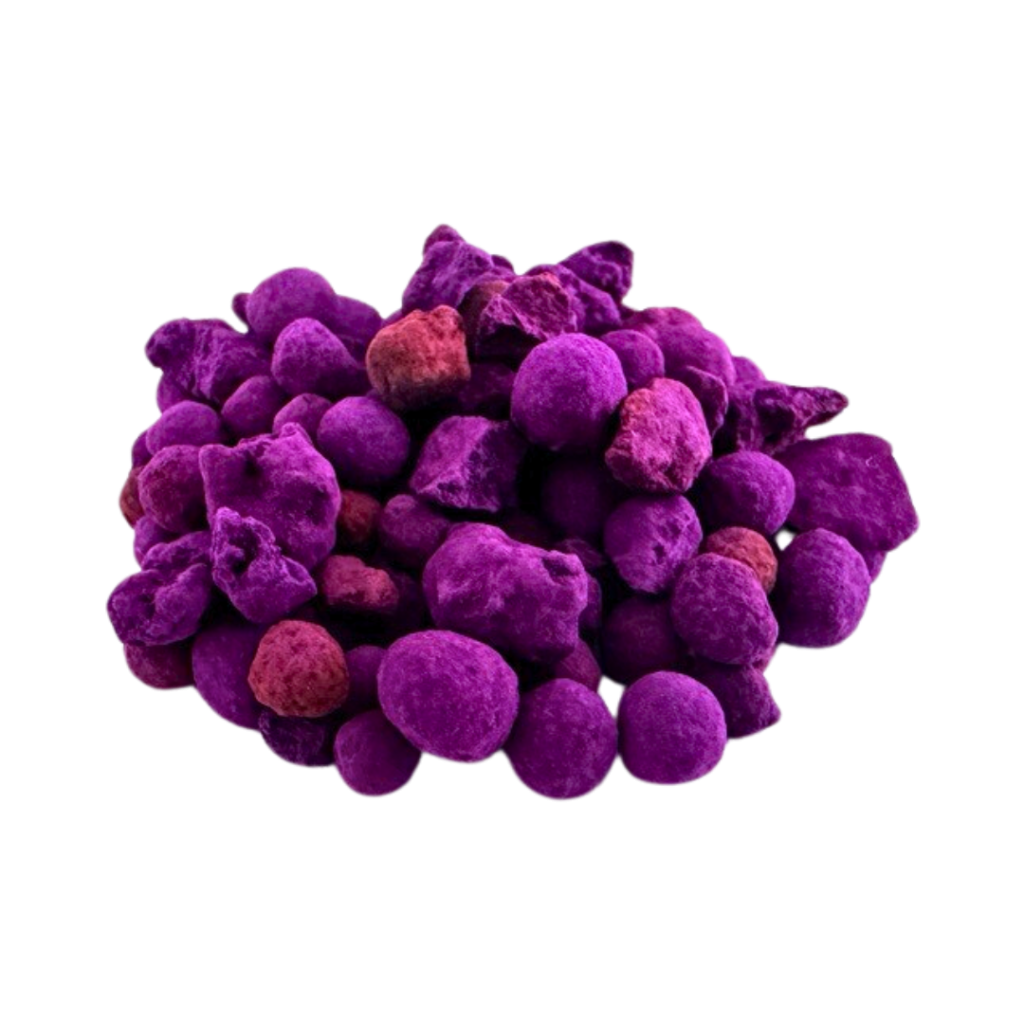

Designed for neutralization of chlorine, hydrogen sulfide and sulfur dioxide, this media is manufactured specifically for the corrosive environments and consists of generally spherical, porous pellets. Composed of carbon, alumina and other binders.

Efficiency

The Puracarb media removes contaminant gases by means of adsorption, absorption, and chemical reaction, and is designed for 99.5% minimum removal efficiency in Purafil systems.

Temperature

-20°C to 51°C (-4°F to 125°F).

Depth

The nominal pellet diameter for a Puracarb media is 1⁄8 “.

Humidity

10-95% RH.

Airflow

Puracarb® is effective with airflows ranging from less than 25cfm to over 100,000CFM and with velocities.

Key Features & Benefits

-

Designed for Corrosive Environments – Specifically engineered to protect equipment and infrastructure in areas with high levels of corrosive gases.

-

Highly Effective Gas Removal – Removes hydrogen sulfide (H₂S), sulfur dioxide (SO₂), and other acid gases that contribute to corrosion and poor air quality.

-

Uniform Impregnation – The impregnant is evenly distributed throughout the pellet, ensuring maximum efficiency and consistent performance.

-

Porous, Spherical Pellets – Optimized structure enhances gas adsorption, increasing contact time for superior contaminant removal.

-

Durable & Long-Lasting – High-quality composition, including carbon, alumina, and binders, ensures extended operational life and minimal maintenance.

-

Versatile Applications – Ideal for data centers, control rooms, museums, manufacturing plants, and other environments requiring gas-phase filtration.

Your Partners In Clean Air

Call 780-436-6960 today to speak with a BGE Clean Air Advisor.