Clearing The Air: Enhanced IAQ And Efficiency At West Edmonton Mall

How West Edmonton Mall Enhanced Air Quality and Efficiency with the TP4500HVT Filter

CHALLENGE

West Edmonton Mall, a sprawling retail and entertainment hub, faces the colossal task of ensuring optimal indoor air quality across its enormous 5.3 million square feet facility. With over 30.8 million annual visitors, the importance of a healthy indoor environment is paramount. The mall’s Facilities & Engineering Team work diligently to maintain air quality in the large-scale facility with scheduled, quarterly, filter replacements of 1,200 fiberglass pad filters across 12 air handling units (AHUs), a labor-intensive and costly operation that was being intensified by rising supply costs and environmental considerations.

OVERVIEW

West Edmonton Mall (WEM), the second largest mall in North America, is a bustling hub for retail stores and entertainment venues. It offers a diverse range of over 800 stores, 100 dining venues, and 12 attractions, including an amusement and water park, indoor ice rink, and a hotel. With average annual foot traffic of 30.8 million visitors, the mall is one of Alberta’s largest and busiest tourist attractions.

This case study highlights how BGE’s TP4500HVT filter improved air quality and efficiency at West Edmonton Mall, delivering significant cost savings and operational benefits for the WEM Facilities & Engineering team.

SOLUTION

SOLUTION

In response to these challenges, BGE proposed a pilot project utilizing BGE’s newest MERV 9/9A pleated panel filter called the TP4500HVT, which was engineered and tested for high performance in turbulent and demanding conditions. The filter’s superior design features high-loft media, robust expanded metal backing, and moisture-resistant frame tape, aiming to extend service life of the filter and reduce overall maintenance demands.

The collaborative pilot project with WEM was intended to:

- Extend filter lifespan beyond the existing 3-4 month replacement cycle.

- Lower total cost of ownership by reducing maintenance, labor, and disposal expenses.

- Contribute to WEM’s sustainability initiatives by minimizing their waste and carbon footprint.

RESULTS

RESULTS

The TP4500HVT filters demonstrated exceptional performance:

- Extended Lifespan: The filters maintained effective operation for 9-12 months, surpassing the previous 3-month cycle and suggested the potential for extending service intervals even further.

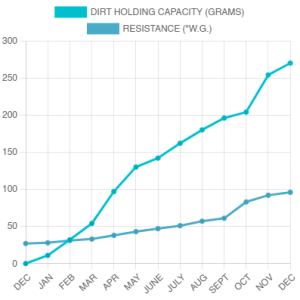

- Exceptional Dust Holding Capacity: The TP4500HVT has a low initial resistance and high dust holding capacity which help reduce energy use to lower operating costs.

- Cost Savings: The switch to TP4500HVT resulted in a direct comparison cost savings, with annual product costs dropping almost 10% as well as 2x savings in labor and disposal costs associated with a more frequent changeout cycle.

- Energy Efficiency: Lower pressure drop over an extended period contributed to reduced energy consumption in air handling operations.

- Sustainability Impact: By decreasing the frequency of filter replacements, WEM has reduced waste, disposal requirements, and the carbon emissions associated with manufacturing and transporting the filters.

- Local Economic Support: WEM’s commitment to using Canadian manufactured goods and partnering with local suppliers underscores its dedication to community and economic sustainability.

10% REDUCTION IN FILTER HARD COSTS

3-4X LONGER SERVICE LIFE THAN A STANDARD PLEATED PREFILTER

3,600 FILTERS SAVED FROM LANDFILLS

2.5X MORE DUST HOLDING CAPACITY THAN A STANDARD PLEATED FILTER

Your Partners In Clean Air

Call 780-436-6960 today to speak with a BGE Clean Air Advisor.